Galvanized steel silos bEST ![]()

Silo construction

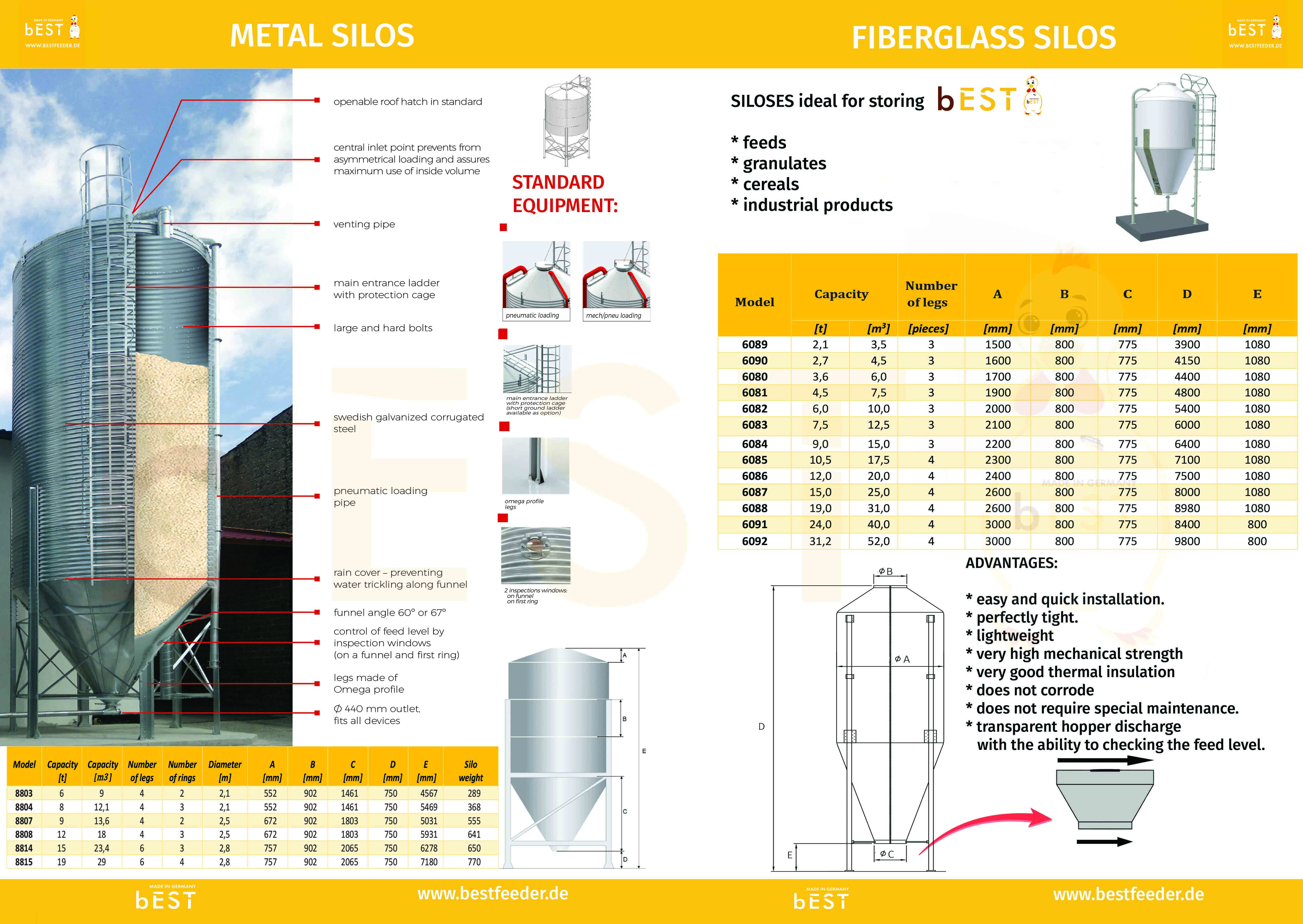

The silo is made of corrugated metal rings, which effectively reflects the sun's rays, protecting the feed from heat, lowering the temperature inside the silo and minimalizing the temperature fluctuations between day and night, what keeps the feed fresh with right humidity

Galvanized body and legs of silo prevents them from corrosion and makes them weather resistant, including temperatures from -30oC to +70oC

The solid legs with aspecial shape and additional crossbars guarantee the stability of the silo. Cone-shaped roof, with a slope of 30 degrees, prevents from snow accumulation

Silo capacity from 5 up to 32 tons

Silo funnel

Made of flat sheet metal with a slope of 60 degrees, which makes the flow of feed easier, also highly greased feed

The inspection hatch (50x40cm)in the silo hopper is the easy access to the inside of the silo and for his cleaning

The inspection window in the upper part of the hopper allows control of the feed level in the silo

The hole at the bottom of silo hopper has a diameter of 44 cm and is suitable for the installation with standard cross conveyors

Loading and vent pipe

They guarantee the right silo functioning. They are used for pneumatic and mechanical loading

The loading pipe (diameter of 100mm) with iron elbows (thickness of 5mm)for protection against abrasion during feed loading, is finished with aluminum quick-release coupling 110mm for pneumatic loading

The vent pipe (diameter of 160mm) with sack holder, keeps optimum air circulation inside of the silo

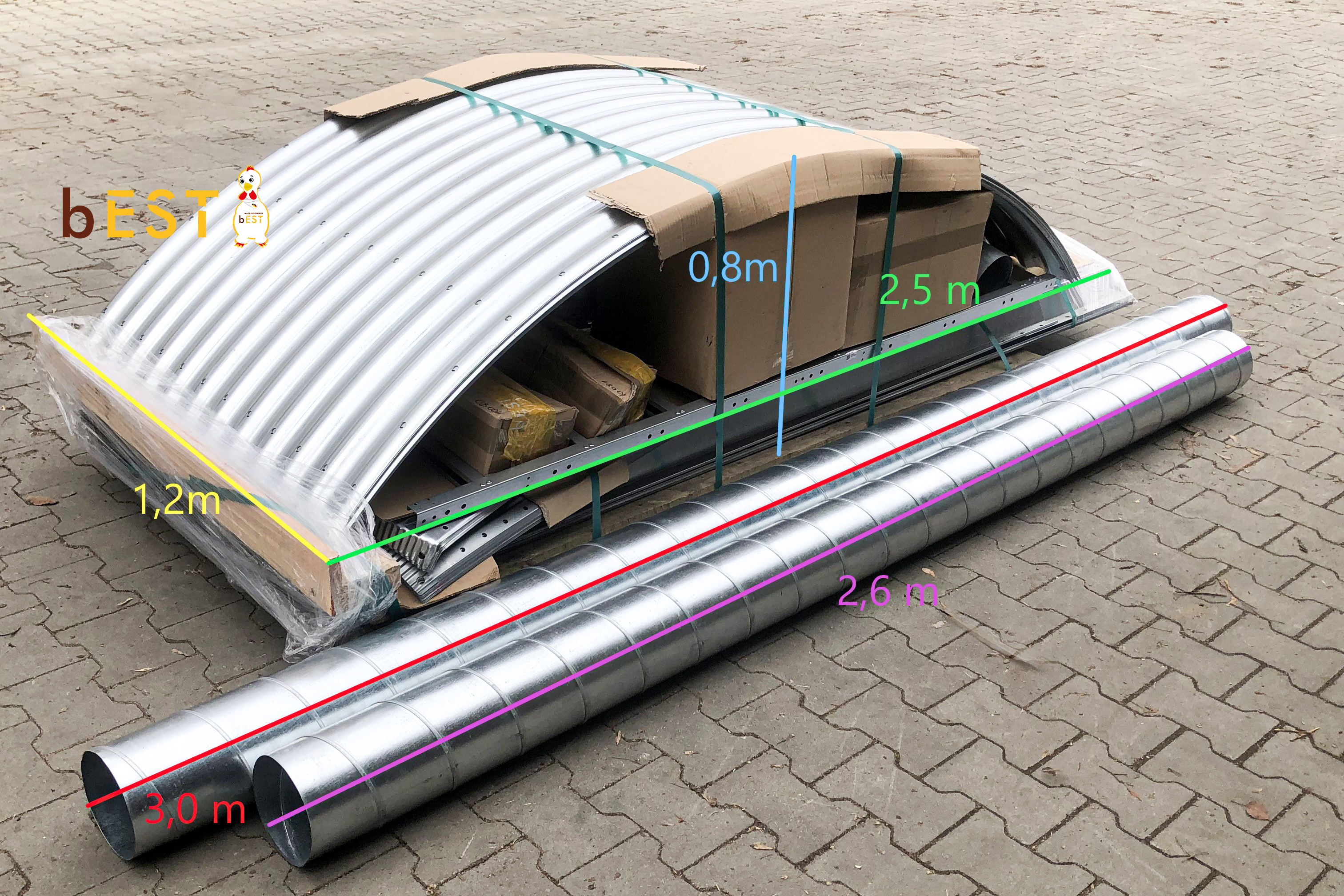

The assembly

On each silo is a list of all components of silo

All elements of the silo have an individual stickers with the name and number corresponding to the list. Assembly instruction is also included

All elements are screwed together and sealed with the silicone (screws, bolts, washers and silicone included)

The silo is placed on a prepared basic using a crane and fixed with special anchors